Engineering Materials for regenerative medicine : A time issue

Tissue Engineering[1] is nowadays an expanding field of research that cleverly combines living cells with supporting materials, often called biomaterials, in order to generate a functional tissue for a human organ (skin, brain, bone ….). The purpose of this activity is twofold. On the one hand, successful tissue engineering can lead to human models of tissues of very high predictive value for testing drug activity or toxicity. This could reduce drastically the use or abuse of animal testing in medical research and pharmacology. On the other hand, the tissue elaborated by engineering could be employed as an implant, that once surgically positioned in a deficient or destroyed organ inside the host is capable of regenerating the lost functions by interaction with the surrounding tissues. In this context of regenerative medicine, attempts to regenerate brain tissues, bones, cardiac muscles after trauma or stroke or to regenerate brown adipose tissues for treating obesity are the object of numerous research articles.

In this contribution we describe this specific engineering activity with a focus on the role and the function played by the material (in this case a biomaterial) which is very original compared to other fields of material science. This specificity originates from the direct interaction of the inert material with living entities (cells) that are subjected to time evolution. The purpose is to conceive and design the right biomaterial (structure, composition, shape) with a view to monitor the transition of the so-called bioartefact (biomaterial + living cells) towards a physiological functional tissue. To this end, we need to consider its surface chemistry, its micro-scale and nano-scale topography, its 3D shape (because physiological cell micro-environments are 3D) but also its ability to co-evolve with cells along different processes such as differentiation, proliferation, colonization, vascularization... In brief, we claim in this article that the right biomaterial for tissue engineering is both a problem of material engineering and time engineering. The state of the art of this domain reveals that the material engineering aspect has been widely documented[2]. However, the consideration of the agency of time has been neglected or disregarded. By pointing out this deficiency, we hope to open new engineering perspectives in tissue engineering.

Context and introduction to the question of time in tissue engineering

A functional physiological tissue is a complex mixture of living cells of different types that have attained a degree of stability often referred to in biology as homeostasis. Overtime, the cells have constructed a stable and operational architecture in adaptation to environmental conditions. This equilibrium is not a steady state but a perpetual evolution in search of a possible operational point, taking into account the environmental changes and the intrinsic time constraints of the basic mechanisms of life linked to gene expression, cell growth, cell division, cell death … At any time, we can claim that the living tissue invents a new configuration. This is adaptation. That does not mean that this new configuration is optimal in the sense of the engineer, but it represents a good fit. A key mechanism for maintaining some stability in this continuous process is linked to the various secretions of the cells that drive the collective architecture of the tissue by inducing numerous feed-back loops. All together these regulation loops monitor nutrition, waste evacuation, mechanical stability, mechanical actuations (for contractile tissues) and various functions linked to the specific tissue under consideration. Among the secreted materials of importance are the macromolecules making the so-called Extra Cellular Matrix (ECM), such as collagen fibers or proteoglycans for example. By adjusting the chemical composition and the density of the surrounding ECM, the cells control the stiffness and porosity of their environment. They create the scaffold on which they adhere, the material through which they interact by chemical or mechanical communications. At any given moment, the physiological tissue can thus be seen as a 3D array of living cells embedded in a 3D mesh of natural biomaterials making up the surrounding matrix. The spatial position, the phenotype of each cell, the 3D configuration of the ECM scaffold, its composition and spatial variations, in brief what we call the architecture of the tissue, are the results of a long process of continuous adaptation in a stable and functional tissue.

Tissue engineering i.e, designing a functional tissue starting from different living cells in culture (either cell lines or primary cells originating from the tissue under construction), thus consists in recreating this specific and complex dynamic architecture. At first glance, to construct a material scaffold mimicking the ECM grid, embedding the different cells of interests seems the best option. Unfortunately, engineers do not have the time that has been necessary to physiological processes for adjusting all the details of the cells+ECM 3D spatial configurations and reaching homeostasis in functional tissues. If we compare this approach to biomimetic design strategies[3], such as problem-based or solution-based strategies, our practice does not consist to the looking of nature as a solution or an inspiration. It consists in developing the right initial conditions for designing a 3D artificial bio-artefact capable of tissue generation during maturation. It is therefore crucial to envision this engineering project not as inventing a precise (yet out of reach) instrument capable of printing a faithful replica of the physiological tissue, but as creating an initial bioartefact capable of providing incentives for the directed generation of homeostatic functional architecture in engineered cells. The purpose is not to fabricate an electronic chip by constructing every semiconducting transistors and metallic connections in a fixed and operational architecture, but rather to position cells (progenitors, stromal, endothelial, …) together with precise guiding materials shaped in 3D in order to allow time to make the final targeted functional system: a living tissue. Nanoelectronics is not the adequate model. It is more like the art of gardening. This idea of involving time in engineered 3D structures have been popularized by the concept of 4D printing, the fourth dimension in addition to the 3 spatial ones, being time. However, we will see in the next section that current 4D printing practices do not adequately describe the agency of time as conceived in tissue engineering.

The agency of time in current 3D/4D approaches

With the popularization of additive manufacturing and the dissemination of 3D printers, new methods have emerged that nurture the sociotechnical imaginary of creating fresh and mature organs with a 3D printing system. In the scientific literature, these technologies and instruments are gathered under the umbrella of Bioprinting techniques[4]. In this section we will see not only that scientists involved in Bioprinting have not considered properly time in their engineering activity but that scientists designing the so-called 4D structures have not had a clear view of the role of time.

The seminal works on bioprinting[5] for generating a tissue or an organ virtually ignored the temporal dimension of the tissues and organs. Indeed, the simple original idea consisted in acquiring high resolution 3D images (RMI, PET-Scan, X-rays tomography) of the targeted tissue then by using 3D injection printers, to reproduce in a biomimetic way with high fidelity to the model, an architecture where all the cells and extra-cellular biomaterials were placed exactly in the same position. This static approach was a scientific standoff. Not only did the 3D images of in-vivo structures not reveal essential details beyond their spatial resolution limit and the available 3D bio-printers could not produce large pieces of tissues, but it was unrealistic for more profound biological reasons. Indeed, even if it was possible to print all the details of the supporting biomaterials, together with mature cells in their right positions, this would totally inhibit the process of organogenesis which is required to obtain a functional tissue or organ. In fact, the printing machine does not print a tissue or an organ but deliver cells and biomaterials in a rigid complex and detailed structure. This artefact does not make the connections between cells, does not resume the history of each cell which is required to bring them in the right phenotypes and in equilibrium or homeostasis with the others. In other words, it is mandatory to include time and evolution at the early stage of the engineering process. Instead of generating a final structure, our alternative project therefore consists in a scenario of regeneration where the 3D-structured biomaterial triggers the evolution of a few selected and engineered cells including: stem cells, stromal cells, endothelial cells, nervous cells…. With our approach, the biomaterial is co-produced by nature and engineering.

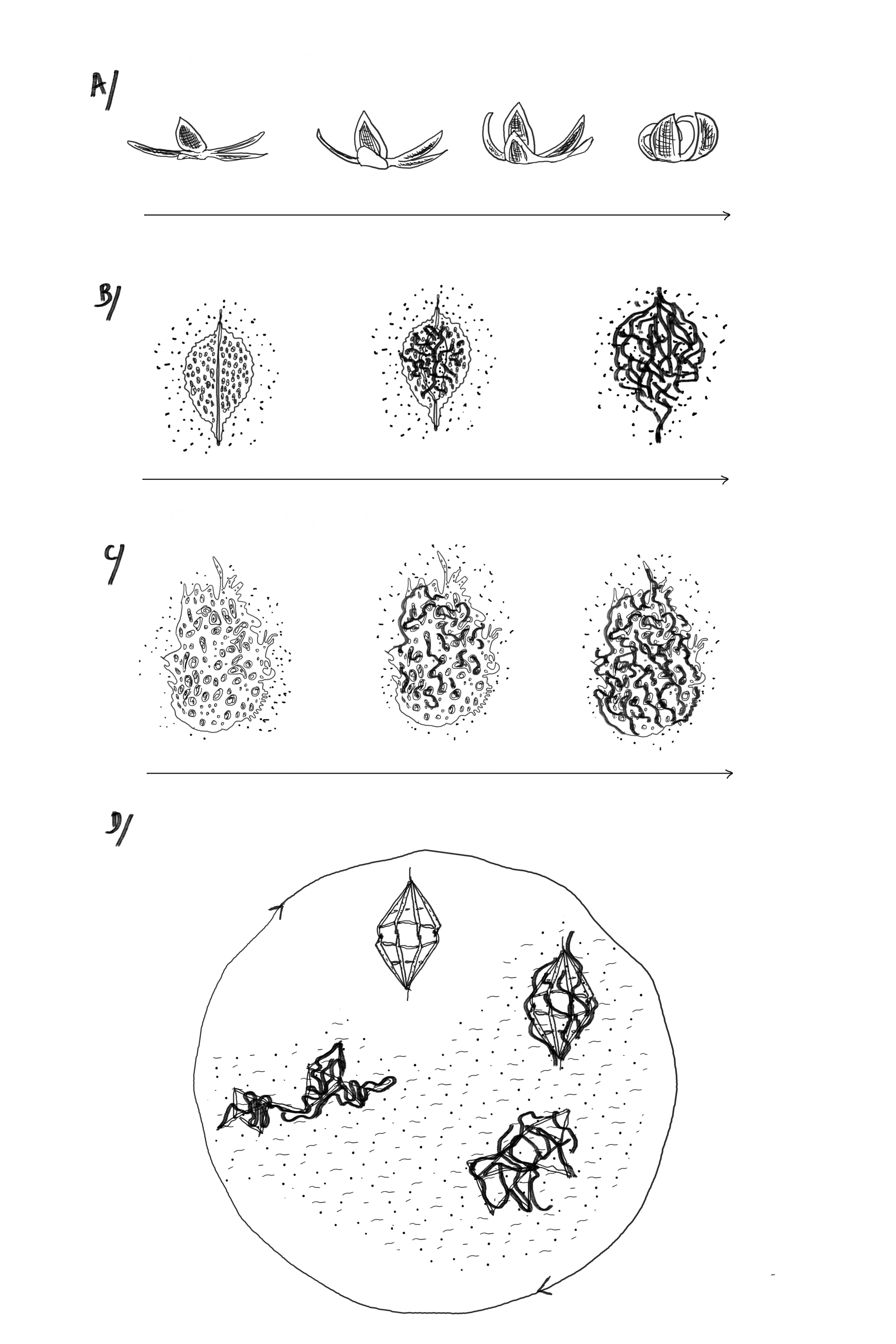

In parallel, the community of 3D printing (not necessarily the one working on tissue engineering or regenerative medicine) has already introduced the fourth dimension of time and has popularized the name of 4D printing[6]. A 4D structure is basically a 3D artefact made of a responsive material that can react under a specific stimulus (temperature, pH, electromagnetic field, light …). Under stimulation the printed material can shrink or expand, or be locally submitted to a mechanical force, and all these effects can result in a modification of the overall 3D structure. Because the 3D structure is not static but can be commanded to change or to move, scientists manipulate temporal events and thus have proposed the phrase 4D printing that has captured the public’s attention. This term is nevertheless disputable. Indeed, these fascinating structures can be better described as 3D responsive structures or actuable 3D structures. They respond on demand to an external signal in a pre-determined way. These structures are really smart but are they really 4D printed? In this design process time refers to the event triggered by the stimulus which is external to the system. The time dimension is not intrinsic to the structure itself; it is not imprinted. What engineers call 4D materials thus refers to programmed or informed matter (see figure 1 part A) shaped in 3D that can undergo a change of state in response to a triggering signal. As a matter of fact, the fourth dimension in the new experimental field of 4D printing, which is supposed to open to the time dimension, seems closely related to a kind of esthetic gesture[7], or a robotic activity[8], where time is just a sequence of programmed and predictable movements or displacements.

Biomaterials and Time in regenerative medicine : some perspectives

This paper claims that the bioprinting activity where materials mimicking the Extra Cellular Matrix are shaped in 3D together with living cells confronts bioengineering with the question of the agency of time in a configuration that has never been addressed before. Indeed, Henri Bergson brilliantly argued that time is the essential trait of living matter. In his book “Creative Evolution”, he wrote: “Wherever anything lives, there is, open somewhere, a register in which time is being inscribed [9].” The design of bioartefacts by bioprinting, mixing engineered materials and living cells thus opens the register of time in a totally novel configuration compared to more conventional manipulation of “time” in 4D printing or when material ageing is investigated.

As seen previously, the question is really to imprint the temporal dimension in the biomaterial itself. The most obvious method for addressing this complex issue would be to create a 3D degradable supporting scaffold for the initial cells. This scaffold could keep the various seeded cells alive and drive their proliferation and differentiation at the initial moments of the culture and subsequently the maturation process of the bioartefact. Once these cells have made their own Extra Cellular Matrix, the scaffold would degrade and gradually leave the floor, allowing the cells to ‘write their own history’ under the operation of time. Implants, made of a biodegradable material, for example silk, are already designed to be dissolved by time. In this strategy of disappearance (see figure 1 part B), the engineered material is designed to disappear once the cells are capable of evolving, thus mimicking the phenomenon of apoptosis in living cells. Another approach would be to create non-degradable supporting scaffolds exhibiting similar properties for the seeded cells at the start of the culture but leaving enough available space for the cells to generate their own homeostatic ECM. This could be envisioned by creating complex highly porous 3D-scaffolds made of nanoscale structures providing strong support and guidance to the cells while limiting the steric hindrance of the supporting structures. Two photons laser beam writing is the typical current 3D technology that could achieve this high level of spatial resolution and should be applied in regenerative medicine in the future[10]. In this strategy of discretion (see figure 1 part C), the nano-engineered material is operational for initiating the genesis but at the end becomes negligible compared to the neo-formed extracellular matrix.

In a longer-term perspective, the 3D bioartefacts required for future regenerative medicine will involve advanced biomaterials shaped in 3D structures capable of triggering the maturation and evolution of seeded cells into a functional tissue as close as possible to a physiological one. Because time is the key process, the 3D biomaterials we need to work on, must include in their design the evolution of the bioartefact. Because cells are in a state of constant adaptation, bioengineers need to create adaptative materials (see figure 1 part D), capable to escort the perpetual reconfigurations of the cells in evolution within the bioartefact. Interesting solutions for that can be found in the expandinging area of 4D printing. Through an ingenious combination of these ideas with the known principles of the evolution of living cells, major advances should be achieved in the near future. We could for example, imagine 3D resilient materials printed at the nanoscale by two photons laser writing and including in their structure reversible points of attachments. Because living cells evolving with in a tissue exert specific patterns of forces on their micro-environment, they could untie and re-fasten on-demand the mechanical links of their engineered scaffold. As a consequence, the engineered material would accompany the evolution of the living cells by its own temporal dimension triggered by the cellular rhythm. Careful investigations of cell nanomechanics, combined with the design of 3D nanoscale printed material with articulated pieces would be necessary to transform this idea into a reality. We have however the feeling that the required knowledges to realise this project already exists across different scientific communities. Designed true 4D biomaterials will be able to co-evolve “symbiotically” with the cells they are hosting when cultured in-vitro and also with the cells of the host, in-vivo, for implantable bioartefacts. Will it be possible for scientists to reach this level of triggering of living processes such as organogenesis? We clearly do not have the answer yet, but part of this answer resides in our capability to integrate time as a process of becoming in our biomaterial constructs.

Conclusion

In this paper we argued that Material and Time are intertwined in a radical novel configuration in the activities of tissue engineering through bioprinting. The constant adaptation of the living cells to the 3D engineered artefactual material in which they are embedded brings in conflict two different conceptions of time. Following Bergson, the material artefact, closed and engineered by our senses, manipulates a “thought time” while the living matter around it, manipulates a “lived time”. This Bergsonian view of time invites engineers to invent disruptive strategies breaking with the conventional practices of the design of synthetic devices and systems. It is by thinking about time as a process of becoming that engineers will create regenerative tissues.

Acknowledgments

The authors acknowledge Bernadette Bensaude Vincent (Université Paris1 Panthéon-Sorbonne) and Viviane Quirke (Oxford Brookes University) for fruitful discussions and language improvements.

DOCUMENTATION

[1] A. Ovsianikov, A. Khademhosseini, V. Mironov, The synergy of scaffold-based and scaffold-free tissue engineering strategies, trends in Biotechnology 36(4) (2028) 348

[2] E.S. Place, N.D. Evans, M.M. Stevens, Complexity in biomaterials for tissue engineering, Nature Material 8 (2009) 457

[3] Badarnah, Lidia, et Usama Kadri. « A methodology for the generation of biomimetic design concepts ». Architectural Science Review 58, nᵒ 2 (3 avril 2015): 120‑33. https://doi.org/10.1080/00038628.2014.922458.

[4] I. Matai, G. Kaur, A. Seyedsalehi, A. McClinton, C.T. Laurencin, Progress in 3D bioprinting technology for tissue/organ regenerative engineering, Biomaterials 226 (2020) 119536

[5] Y. S. Zhang, R. Oklu, M.R. Dokmeci, A. Khademhosseini, Three-Dimensional Bioprinting Strategies for Tissue Engineering, Cold Spring Harb Perspect Med. 2018 Feb 1;8(2):a025718.doi: 10.1101/cshperspect.a025718.

[6] S. Tibbits, The emergence of “4D printing”, TED Conference (2013), https://www.ted.com/talks/skylar_tibbits_the_emergence_of_4d_printing

[7] Sydney Gladman, A., Elisabetta A. Matsumoto, Ralph G. Nuzzo, L. Mahadevan, et Jennifer A. Lewis. « Biomimetic 4D Printing ». Nature Materials 15, nᵒ 4 (avril 2016): 413‑18. https://doi.org/10.1038/nmat4544.

[8] Wehner, Michael, Ryan L. Truby, Daniel J. Fitzgerald, Bobak Mosadegh, George M. Whitesides, Jennifer A. Lewis, et Robert J. Wood. « An Integrated Design and Fabrication Strategy for Entirely Soft, Autonomous Robots ». Nature 536, nᵒ 7617 (août 2016): 451‑55. https://doi.org/10.1038/nature19100.

[9] Bergson, Henri. [1907] Creative Evolution,. Traduit par Arthur Mitchell. Henry Holt. New York, 1911, p. 16, our traduction.

[10] A ; Accardo, M.C. Blatche, R. Courson, I. Loubinoux, C. Vieu, L. Malaquin, Two-photon lithography and microscopy of 3D hydrogel scaffolds for neuronal cell growth, Biomedical Physics and Engineering Express 4, 2 (2018)

L'auteur/autrice

Ville : Toulouse

Pays : France

Micro/Nano fabrication

NanoBiosciences

Nanomedecine

Bio-Impression

Biopsie Liquide

Bio-Impression

Analyse ultra-sensible de traces

Interafce Arts/Sciences

Contributeurs

/Contributrices